What is an Air Preparation Unit?: A Complete Guide

Air Preparation Units (APU) play an important role in global pneumatics, ensuring that compressed air systems operate successfully and reliably. Pneumatic structures rely on smooth, dry air to achieve maximum overall performance, and APUs are designed to simply deliver that.

This guide will guide you through the meaning of aerial training aids, how they work, their key ingredients, and their capabilities, drawing on insights from authoritative assets such as Airmax Pneumatics Ltd.

Trust Airmax Pneumatics Ltd. is the leading Pneumatics Valve Manufacturer in Ahmedabad, India.

What is an air preparation unit?

An Air Preparation Unit (APU) is a device designed to treat and compose compressed air before it is used in pneumatic equipment. Compressed air often contains impurities such as water vapor, oil particles, and strong particles that can damage pneumatic equipment, reduce performance, and even lead to equipment failure. APUs ensure that the air used in these systems is clean, dry, and regulated to the correct pressure levels.

APUs are important in many industries such as automotive manufacturing, food processing, electronics, and packaging. Whether it’s pneumatic gear drive, valve control, or actuator control, easy and ready air is key to longevity and overall gadget performance.

What is the air preparation unit for?

The primary reason for an air conditioning unit is to ensure that the air supplied to the pneumatic structures is of excessive quality. Pneumatic designs require constant air stress and cleanliness to function effectively. APUs help achieve this through contaminant shedding, voltage regulation, and essential air lubrication.

Key Uses of the Air Trainer Unit include:

Filtering: Removes solid particles, oil, and moisture.

Pressure Regulation: Maintaining the exact air pressure for the best possible operation.

Lubrication: Adding a controlled amount of lubricant to prevent it from sticking to pneumatic components.

In this way, APUs reduce system maintenance, minimize downtime, and extend the overall life of pneumatic structures.

How does the air preparation unit work?

The Air Preparation Units works with the treatment of compressed air in stages. The traditional Air Preparation process involves filtering, regulating, and lubricating the air as it flows through the system. Let’s break down these steps:

1. Filtration: Air passes through a filter to remove impurities such as dirt, grime, oil, and water. These particles can otherwise clog and damage sensitive pneumatic components. The filter separates moisture and various impurities, which enables smooth air transport.

2. Pressure regulation: After filtration, the air moves through the pressure regulator. Pneumatic systems require air at a certain load for easy and efficient operation. The regulator ensures that the air tension is within the preferred variation, preventing fluctuations that could damage the system.

3. Lubrication (Optional): Some designs require lubrication and a lubricant may be introduced into the unit. The lubricator injects an exceptional oil mist into the air, helping to reduce friction and wear inside the shifting components of pneumatic equipment and equipment.

Once the air has passed through these layers, it is smooth, dry, and ready to be used by pneumatic equipment with maximum performance and minimal threat of damage.

Air preparation unit parts:

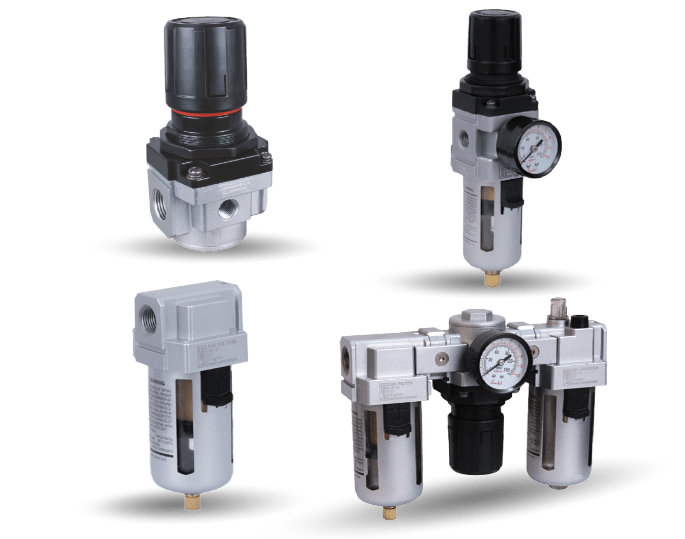

An air conditioning unit has several key ingredients to filter, condition, and lubricate compressed air. The most important elements of the APU include:

Filter: Removes impurities from the air such as stable impurities, oil, and water.

Pressure regulator: Controls and maintains constant air pressure and ensures safe operation of pneumatic equipment and devices.

Lubricant: Adds an oil mist to the air (if needed) to ensure proper lubrication of shifting components in pneumatic devices.

Drain: Collects and removes accumulated water and particles from the system.

Gages: Show stress levels, help operators on screen, and adjust the gadget as needed.

These ingredients are regularly mixed into a single compact unit called an FRL (Filter, Regulator, Lubricator) assembly, but can also be adjusted separately based on system needs.

Functions of the air conditioning unit:

The number one function of an aviation training unit revolves around providing first-class air and instrument safety. These include:

1. Filtration: Removal of harmful impurities and moisture from compressed air, preventing damage to pneumatic additives.

2. Pressure regulation: Maintaining the required air pressure for efficient operation of the device.

3. Lubrication: In some cases including oil into the air to reduce wear on pneumatic equipment.

4. Dehumidification: Condensed water in compressed air can cause corrosion and reduce performance. The APU effectively gets rid of this moisture and protects the machine.

By featuring these features, air training gadgets increase the efficiency, protection and longevity of pneumatic systems.

Types of air Preparation units:

There are unique forms of aviation education units to have depending on the exact desires of the company:

FRL Basic Units: Includes drain, regulator, and lubricator in one assembly. These are widely used in expanded pneumatic structures.

Heavy-Duty Units: Designed for more demanding programs, along with those seen in industrial environments, where better air volumes and stricter filtration are required.

Modular Units: Offer flexibility and allow operators to use or remove additives entirely according to the unique needs of the pneumatic system.

Why are air preparation units important?

Air training units are important for maintaining the reliability and overall performance of pneumatic structures. Without proper air conditioning, impurities can cause:

- Greater wear of pneumatic additives.

- Reduced device efficiency due to inconsistent pressure levels.

- Higher protection fees against system disasters due to dirt, moisture, and oil contamination.

- System downtime could affect production output and lead to high price delays.

By providing easy, dry, regulated air, APUs help increase the lifestyle of pneumatic systems and increase typical operating efficiency.

Conclusion

Air Preparation Devices are essential to any pneumatic machine, offering the easy, dry, and properly compressed air necessary for clean and environmentally friendly operation. By filtering debris, regulating pressure, and adding lubrication when needed, APUs help prevent equipment damage, reduce guarding, and extend the life of your air tools and machinery.