Single Vs Double Solenoid Valve: Choose the Right Option

Choosing the perfect solenoid valve is crucial for the most effective overall performance when designing or upgrading a pneumatic system. Choosing between single and double solenoid valves can extensively impact your machine’s operation. In this complete manual, we’ll explore the differences among these types of valves, their working concepts and packages, and how to pick the proper one for your needs.

Understanding Solenoid Valves

Solenoid valves are electromechanical systems used to control the flow of fluids or gases in industrial applications. They include a solenoid (a coil or cord) and a valve mechanism. When electrical current passes through the solenoid, it creates a magnetic field that actuates the valve, allowing or blocking the flow. Because of their precision and reliability, solenoid valves are critical components in various industries, including production, automotive, and aerospace.

Single Solenoid Valves

A Single solenoid valve capabilities one solenoid coil and usually operates in a function configuration. In its default kingdom, the valve is held in role through a spring. When the solenoid is energized, the valve shifts to its energetic role, allowing go with the flow. Once the strength is eliminated, the spring returns the valve to its original country.

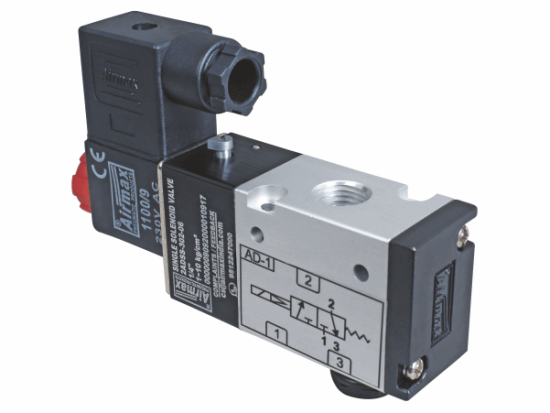

3/2 Way Single Solenoid Valve

Key Characteristics:

Operation: Energizing the solenoid shifts the valve to its active function; de-energizing returns it to the default kingdom via a spring mechanism.

Power Consumption: Requires non-stop strength to preserve the energetic function.

Fail-Safe Position: In the occasion of a strength loss, the valve returns to its default position, making it suitable for applications wherein a selected fail-safe nation is important.

Applications Of Single Solenoid Valves:

Single solenoid valves are perfect for applications in which it’s essential to have the valve go back to a recognized role upon energy loss. They are generally used in safety applications and techniques requiring a default state when not actively controlled.

Double Solenoid Valves

A double solenoid valve is equipped with two solenoid coils and can operate in a two-position or three-position configuration. Each solenoid controls a specific position of the valve. Energizing one solenoid shifts the valve to at least one position, whilst energizing the other solenoid shifts it to the opposite position. Notably, the valve stays in its remaining role even after power is eliminated, due to a detent mechanism.

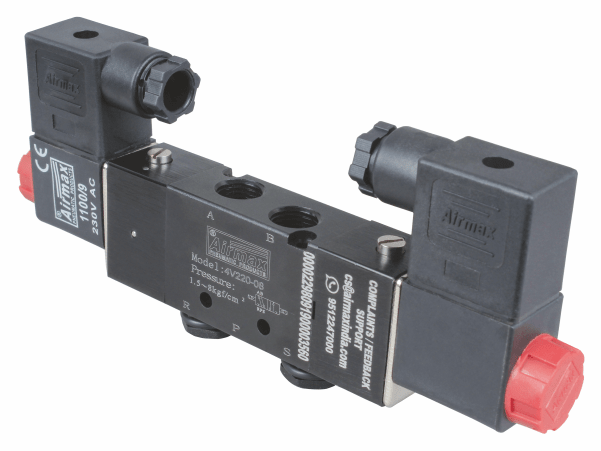

5/2 Way Double Solenoid Valve

Key Characteristics:

Operation: Energizing one solenoid moves the valve to a selected role; energizing the alternative solenoid moves it to the opposite role.

Power Consumption: Requires power handiest all through the transition among positions, making it greater energy-efficient for sure packages.

State Retention: Maintains its last function after being de-energized, which is beneficial in programs wherein the valve’s nation has to continue to be unchanged at some point of a strength loss.

Applications Of Double Solenoid Valves:

Double solenoid valves are suitable for applications where keeping the final operational state is crucial, even all through strength interruptions. They are often utilized in complicated automation techniques and machinery that require constant operational states.

Choosing the Right Valve for Your System:

When identifying single and double solenoid valves, remember the following elements:

1.} System Requirements:

Determine whether your utility necessitates a default fail-safe position (favoring single solenoid valves) or if maintaining the closing function all through power loss is important (favoring double solenoid valves).

2.} Energy Efficiency:

If minimizing strength intake is a priority, double solenoid valves can be greater appropriate, as they require energy most effectively at some stage in kingdom transitions.

3.} Control Complexity:

Assess the complexity of your control system. Double solenoid valves provide extra control options but may additionally require a greater state-of-the-art control setup.

4.} Application Environment:

Consider the operational surroundings, such as factors like vibration, temperature, and ability exposure to contaminants, which may influence the valve’s overall performance and toughness.

Read more about different types of pneumatics valve in another insight here:

About Airmax Pneumatics Ltd.:

When it comes to superb pneumatic solutions, Airmax Pneumatics Ltd. Stands proud as a leading manufacturer in Ahmedabad, India. Airmax has built popularity for excellence in the layout and production of pneumatic cylinders, directional manage valves, rotary joints, and FRL Units. Our commitment to high quality and customer satisfaction makes us dependent on associates for industries seeking dependable pneumatic valves.

Conclusion

Selecting the precise solenoid valve is essential for the efficiency and reliability of your pneumatic device. Understanding the variations between single and double solenoid valves enables you to make an informed choice that aligns together with your software’s precise wishes.

Whether you require the fail-safe characteristics of a single solenoid valve or the state retention features of a double solenoid valve, We Offers a comprehensive variety of answers to satisfy your requirements.

By carefully comparing your application’s needs and consulting with experts, you can make sure you select a solenoid valve, that enhances performance, protection, and energy efficiency for your operations.