Pneumatic Cylinders in Packaging: Boosting Speed and Accuracy

In the fast-moving world of industrial packaging, rapidity and accuracy are important. Whether sealing, labeling, or filling, packing machinery must perform efficiently to meet production demands without affecting quality. The pneumatic cylinder is an essential component to use in this situation.

At Airmax Pneumatics Ltd. we are the superior Pneumatics Cylinders Manufacturer in Ahmedabad, India. This equipment plays a role in modern packaging applications, offering the best accuracy and speed to keep processes operating smoothly.

Importance of Speed and Accuracy in Packaging Machinery:

Speed and precision in packing equipment are not only suitable; they can be critical. With growing consumer demand and the requirement for efficient operations, packing lines should maintain high throughput rates while ensuring that every package is handled carefully.

Mistakes like as misplaced labels or incorrectly sealed programs can result in expensive recalls and damage to a logo’s recognition. This is where pneumatic cylinders come into play.

Pneumatic cylinders, also known as an air cylinder or a pneumatic air cylinder, transform from compressed air into linear motion, facilitating quick and precise movement.

Their ability to deliver constant overall performance under several kinds of environments makes them ideal for packing machinery, where every second counts and precision is crucial.

The Role of Pneumatic Cylinders in Packaging Applications:

An air cylinder is a flexible addition used in various types of packaging applications, including pick-and-place operations, carton shaping, sealing, and product sorting.

Pneumatic Cylinder

They are well-known for their dependability and effectiveness, making them the preferred choice for a wide range of packing solutions.

Pneumatic cylinders contribute to the speed and precision required in large-scale manufacturing operations by allowing for simple and controlled motions.

Factors Affecting Pneumatic Cylinder Speed:

Several factors impact the velocity at which a pneumatic cylinder operates, including:

1. Supply Air Pressure: The amount of compressed air supplied to the cylinder directly affects its speed. Higher air stress often results in faster performance; however, it must be controlled to prevent unnecessary wear and tear.

2. Piping and Valve Size: The size of the piping and valves connected to the cylinder could affect airflow and speed. Proper size ensures optimal overall performance.

3. Cylinder Piston Area: The pressure generated by a cylinder is determined by its piston area. A large piston position can move heavy loads but can also restrict speed.

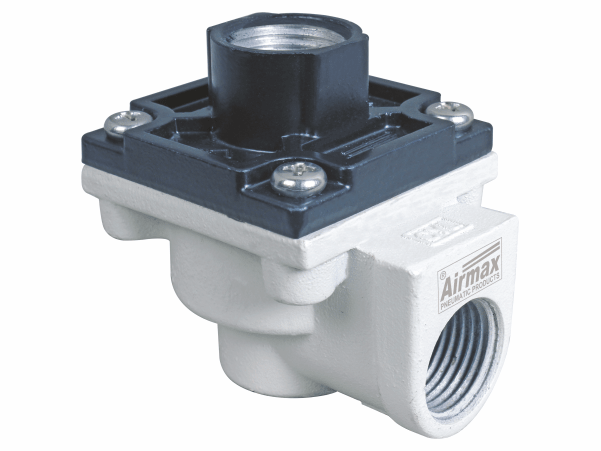

Quick Exhaust Valves:

These valves allow for the speedy escape of air from the cylinder, which speeds up the return stroke and overall cycle time.

Quick Exhaust Valve

By optimizing these factors, producers may enhance the overall performance of pneumatic cylinders in packing processes, resulting in quicker and more precise operations.

Advantages of Pneumatic Cylinders for Packaging:

Pneumatic cylinders have various benefits in packing applications, including:

1. Speed and Precision: Pneumatic cylinders offer fast and accurate motions, essential for high-speed packing operations.

2. Cost-Efficiency: Compared to other options for actuation systems, pneumatic cylinders are extremely affordable and have a long lifespan with minimal maintenance.

3. Safety and Reliability: Pneumatic systems are naturally safe without electrical hazards. They are also extremely reliable, ensuring consistent performance even in harsh environments.

4. Versatility: Pneumatic cylinders are easily adapted to a wide range of packing responsibilities, from easy movements to complex multi-axis operations.

5. Simple Integration: Pneumatic elements are simple to build and incorporate with existing packing gear, resulting in less downtime during the implementation.

6. Energy Efficiency: In some cases, pneumatic structures can be more energy-efficient than electric or hydraulic systems.

7. Clean and Contamination-Free Operation: Pneumatic cylinders require no lubricants or oils to work, which makes them ideal for packing items where cleanliness is essential.

Best Applications of Pneumatic Cylinders for Packaging:

- Prioritize cost-effectiveness: by selecting cylinders that strike a balance between performance and price, ensuring a worthwhile investment.

- Versatility and Flexibility: Choose cylinders that can handle a variety of packaging operations, allowing for a simple model to adjust manufacturing requirements.

- Efficiency and Productivity: Choose cylinders that improve the overall performance and productivity of your packing line, resulting in faster cycle times and higher throughput.

Conclusion

Pneumatic cylinders are critical to the success of contemporary packaging technologies, offering the speed, accuracy, and dependability required to keep up with the demands of current production processes.

You may improve your packing processes for maximum efficiency and precision by understanding the elements that influence their performance and selecting the right cylinders for your specific requirements.

At Airmax Pneumatics Ltd, with the help of our skilled professionals, you can choose suitable pneumatic solutions so that your packaging system achieves new heights of efficiency and quality, ensuring that your products reach the market on time and seamlessly. Best Pneumatic Cylinders for Packaging are available to meet various needs in the industry.