Foot Operated Valves: Hands-Free Control for Pneumatic Systems

In the Pneumatic Industry, efficiency and protection are the best things that provide ease of operation. One component that significantly works well for each is the Pneumatic Foot Valve. These valves allow operators to control pneumatic systems hands-free, growing productivity, safety, and precision.

At Airmax Pneumatics Ltd., we recognize how these valves allow operators to manipulate pneumatic structures with arms free, increasing productivity, protection, and precision. We also realize how pivotal such applications are in streamlining complex industries while maintaining user safety.

What Are Foot-Operated Valves?

As the name implies, Foot-operated pneumatic valves are controlled by a foot, Unlike manual or automated hand-controlled valves, they free up the operator’s hands, enabling multitasking, which is invaluable in high-demand environments like manufacturing plant life or assembly lines. These valves control the flow of air or other gases in pneumatic systems, ensuring the precise operation of the industrial applications.

Why Are They Necessary?

Speed and accuracy are crucial in industries requiring close-on pneumatic systems. Foot valves offer an easily operated and efficient solution, allowing users to control equipment truly through an urgent pedal with their foot. These valves allow for extended flexibility, speed, and multitasking while reducing the risk of manual managing errors.

Additionally, foot valves are crucial in ensuring safety. By distancing the operator from moving components, it minimizes risks of damage from rotating or unsafe applications. The operator can act from a secure distance, maintaining control without the risk of close interaction.

Benefits of Foot-Operated Valves in Pneumatic Systems

1.} Hands-Free Operation:

The primary advantage of foot valves is their hands-free functionality. In high-demand environments, operators can perform various responsibilities whilst controlling pneumatic systems, without diverting their attention from the application.

2.} Enhanced Safety:

Foot valves ensure the operator maintains a safe distance from potentially hazardous operations. By using their feet for control, operators reduce the risk of injuries because of direct contact with moving or dangerous machine arts.

3.} Increased Productivity:

By automating controlling responsibilities, these valves significantly reduce manual hard work. This results in smoother workflows, reduced downtime, and heightened productivity.

4.} Precision and Speed:

Foot valves are known for their quick response time, allowing for immediate control over airflow and pressure. This ability to rapidly start or stop operations contributes to the precision required in manufacturing environments.

5.} Easily Operated:

Prolonged manual operation can lead to fatigue or injury. With foot-operated valves, the risk of repetitive stress accidents is decreased, promoting ergonomic work, situations and enhancing general worker consolation.

6.} Versatility:

These valves are available in various types and configurations, making them adaptable to different applications, which include high-pressure applications. Their flexibility allows them to be implemented throughout one-of-a-kind industrial applications, from light to heavy-duty operations.

Key Components of Pneumatic Foot Valves

Foot-operated pneumatic valves typically consist of:

- Housing: Protects internal additives from harsh situations.

- Valve Mechanism: Controls airflow and consists of seals and is derived to prevent leaks.

- Foot Pedal: The consumer interface that activates the valve, supplying feedback.

- Actuation Mechanism: Connects the pedal to the valve, ensuring fast and accurate control.

Each factor works efficiently to ensure green and easy operation, even in demanding situations.

Applications Pneumatic Foot Valve Across Various Industries

Foot-operated valves are flexible and located throughout several industries. In manufacturing, they may be crucial for controlling conveyor belts, presses, and different computerised equipment. In automation industries, those valves streamline assembly applications, allowing employees to be conscious of other crucial responsibilities. They are also used in Medical Equipment, where precision control of pneumatic application. is crucial.

In these environments, the valves no longer best boost productiveness, however additionally growth safety through minimising the need for workers to manually deal with pneumatic structures.

In these environments, the valves not only boost productivity but also increase safety by minimising the need for workers to manually handle pneumatic systems.

Choosing the Right Foot Valve

When deciding on a pneumatic foot valve on your device, numerous factors ought to be considered:

1.} Pressure and Flow Capacity: Ensure that the valve matches the system’s stress necessities to prevent inefficiencies.

2.} Material Durability: Valves uncovered to harsh environmental conditions, which include extreme temperatures or corrosive materials, must have sturdy housing substances.

3.} Operator Comfort: Ergonomically designed pedals reduce operator fatigue, enhancing general device performance.

4.} System Compatibility: The valve must combine seamlessly with the pneumatic machine’s fittings and strain requirements.

At Airmax Pneumatics Ltd, we offer 3/2 (Detent/Spring Return) & 5/2 (Detent/Spring Return) foot-operated valves that cater to those unique wishes. Our valves ensure seamless integration, durability, and excessive overall performance.

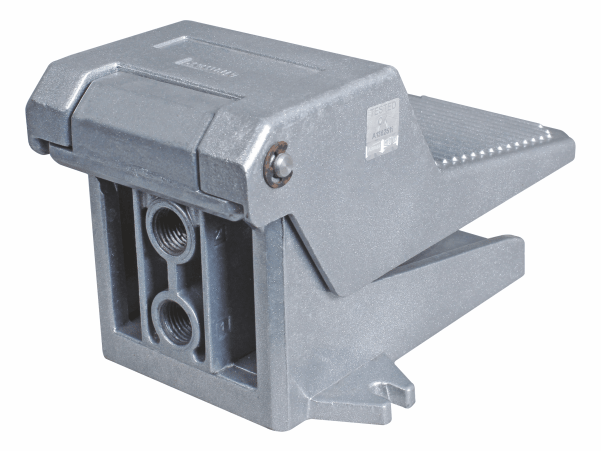

3/2 foot operated valve

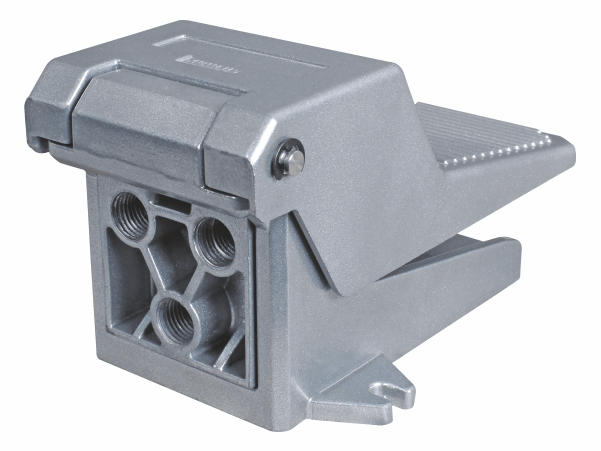

5/2 foot operated valve

Installation and Maintenance for Pneumatic Foot Valve

To make sure that foot valves operate optimally, accurate installation and ordinary maintenance are critical. The proper installation consists of:

- Ensuring airtight connections to keep away from strain leaks.

- Positioning the valve for the smooth foot to get admission without compromising on safety.

- Conducting exams publish-set up to affirm clean operation.

In phrases of upkeep, frequently examining the foot pedal and valve mechanism for putting on is fundamental. Lubricating components and replacing worn seals make certain lengthy-time period functionality.

At Airmax Pneumatics Ltd, we provide recommendations and protection guidelines to increase the lifespan of our foot-operated valves, making sure you get first-rate overall performance from your systems.

Industry Standards and Safety

Foot valves are regulated under worldwide standards which include ISO and DIN to ensure reliability and safety. Adhering to these requirements, our foot valves at Airmax Pneumatics Ltd are designed to fulfil the very best enterprise benchmarks, ensuring safety and sturdiness. We prioritise the most effective, most appropriate overall performance but also compliance with the trendy safety guidelines.

Future Trends in Pneumatic Foot Valves

The destiny of pneumatic foot valves is transferring toward smarter, extra energy-efficient designs. Innovations which include sensor integration for real-time tracking, and IIoT (Industrial Internet of Things) connectivity, are becoming more universal. These advancements intend to enhance automation, reduce operational costs, and boost precision on top of things.

At Airmax Pneumatics Ltd, we’re at the vanguard of those innovations, constantly developing valves that cater to the ever-evolving desires of modern industries.

Conclusion

Foot-operated valves are a vital component of pneumatic systems, imparting fingers-free control, multiplied safety, and heightened efficiency. At Airmax Pneumatics Ltd, we provide a wide variety of quality foot valves that meet specific industrial requirements. Whether you’re seeking to increase productivity, make certain safety, or destiny-evidence your operations with modern technology, our valves supply superior overall performance tailor-made to your wishes.

For more information or help in deciding on the proper foot-operated valve for your pneumatic application, visit Airmax Pneumatics Ltd today!