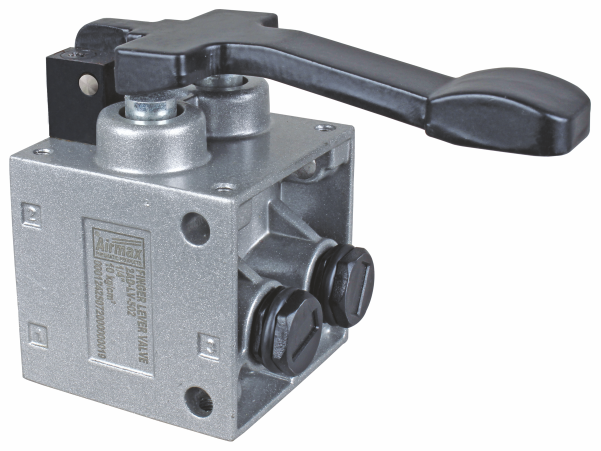

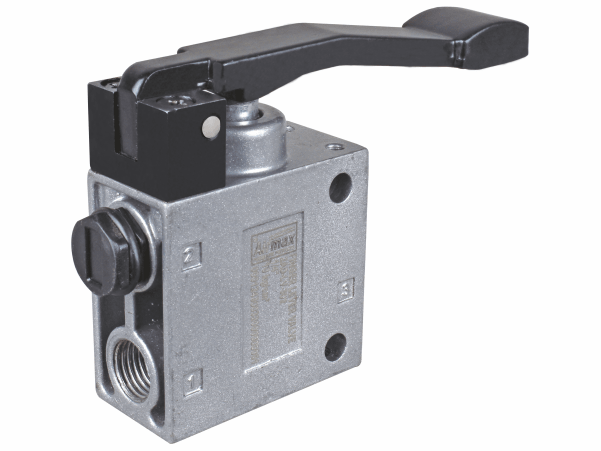

Poppet Type Finger Lever Valve: A Compact Solution for Quick Pneumatic Control

Pneumatic control systems play a significant role in various industries, offering fast and environmentally friendly movement through compressed air. These structures are the backbone of automation, manufacturing, packaging, and various industrial applications that require precision and speed.

A key component of these systems is the valve that controls the airflow. One such valve that stands out for its compact size, performance, and ease of use is the Poppet Type Finger Lever Valve.

This article explores what makes the poppet-type lever valve an essential choice for pneumatic actuation systems, especially in industrial applications. We will look at its functionality, advantages, and how to choose the right valve for your industrial applications.

What is a poppet-type lever valve?

A Poppet-type valve is a mechanism designed to control airflow in a pneumatic application. It works by using a poppet valve—a valve that seals an opening in the direction of flow or stress until a force such as air or mechanical input pushes it open. Depending on the position of the poppet, the valve either allows or blocks the flow of air. Unlike other valve types, the poppet valve normally offers faster response times and can handle high pressure without leakage.

The finger lever mechanism refers to the manual control ever attached to the valve. This lever allows the operator to quickly and efficiently open and close the valve with just a flick of the finger. The ergonomic design enables clean operation, and reduces operator fatigue, making it the perfect choice for requiring quick control in industrial applications.

Principle of operation of poppet valves:

In a pneumatic system, compressed air is supplied through pipes. A poppet valve, operated by a finger lever, regulates this air by allowing it to flow around or be blocked. When the lever is depressed, the plate is displaced, thereby actuating the valve and allowing air to flow. When released, the valve closes as the plug returns to its sealed role, reducing airflow. This simple but pretty green mechanism makes it ideal for applications requiring short handling and high flow capacity.

Key advantages of poppet type lever valve:

1.} Compact design:

One of the number one advantages of the poppet-type finger lever valve is its compact design. In industrial environments where space is often limited, a smaller valve can make a huge difference. These valves are designed to fit tight spaces without compromising overall performance. For industries managing complicated setups or restricted environments, the compact size of this valve allows for less complicated setup and operation.

2.} Quick Activation:

In business packages, speed is often the deciding factor. The finger lever mechanism allows for quick actuation; the operator can quickly move the valve between the open and closed positions with minimal effort. This makes the valve a great answer to procedures where quick responses are required, along with stress or automatic structures. In addition, the short response time reduces downtime and complements productivity.

3.} Durability and durability:

Industrial environments can be harsh, with valves regularly exposed to dust, heat, and high pressure. The voltage-type lever valve is made to be durable and long-lasting even in these demanding conditions. These valves are made of strong, wear-resistant materials and provide long life, making them a cost-effective solution for agencies.

4.} High flow capacity:

Despite its compact length, it offers a tension lever valve high-flow capacity. This means it can handle large volumes of air without slowing down the machine or causing inefficiencies. The high flow charge makes it ideal for industries where airflow is essential, including packaging, automation and manufacturing.

5.} Versatility:

Another huge benefit is the versatility of this valve. It can be used in a wide range of pneumatic packages, from machine control in automated production lines to work pneumatic equipment in workshops. The valve’s ability to function properly in a variety of environments makes it a popular choice for exceptional business sectors.

Applications in industrial pneumatic systems:

The Poppet-type Finger Lever valve is used in various industries due to its speed, compact design, and durability. Some of the key sectors in which these valves are typically used include:

Manufacturing: In assembly lines and automatic processes, where fast and specific air regulation is critical.

Automation: These valves help control air-operated devices, machines, and systems.

Packing: Quick activation and high flow capacity make them perfect for packaging machines that require reliable and short air handling.

Material handling: In systems that circulate or handle goods using pneumatic power, poppet-type valves ensure easy operation.

Comparison with Other Manual Control Valves:

Compared to the various types of manually operated valves including Gate Valves or Sluice Valves, the Poppet Type Finger Valve provides faster actuation and increased air control. In addition, the finger lever designs offer extra special leash handling, making it easier for operators to handle in fast-paced environments.

How to Choose the Right Finger Lever Valve for Your Needs:

Size: Depending on the available space in your system, select the valve size that fits without affecting overall performance.

Pressure Rating: Make sure the valve can handle the pressure of your pneumatic application. Most poppet valves are designed for high-pressure systems, but it’s usually important to check.

Flow Rate: A high flow capacity is an indicator of a poppet valve, but you still need to confirm that it meets your application’s air volume requirements.

Material compatibility: The materials used in the manufacture of the valve must correspond to the environment in which it will be used. For example, a corrosive environment may require stainless steel or similar resistant materials.

Customization options:

At Airmax Pneumatics Ltd., we understand that every system has unique requirements. That’s why we offer customization options for our poppet-type lever valves. Whether you want a select size, material, or flow rate, our team of professionals can customize a product to your specific specifications. This flexibility ensures that our valves perform optimally for your specific application.

Tips for maintenance and long-term use:

Regular Inspection: Regularly check for wear and tear, specifically in high-pressure environments.

Cleaning: Keep the valve free from dust and particles to save you from blockages.

Lubrication: Use precise lubricants to reduce friction and expand the valve’s lifestyles.

Replacement Parts: Ensure you have access to replacement parts, like seals and levers, to avoid downtime when preservation is needed.

Conclusion:

The poppet-type finger lever valve is a compact, long-lasting, and flexible solution for pneumatic control systems. Its quick actuation, high flow ability, and long-lasting design make it ideal for various industrial applications.

At Airmax Pneumatics Ltd., we provide an extensive variety of poppet-type finger lever valves, with customization options to meet your specific needs. By choosing the right valve and maintaining it well, industries can ensure smooth and green pneumatic operations, contributing to advanced productivity and cost savings.